2.5.24

Advanced COBOT Welding Technology: MJE Livestock Equipment Embraces the Future

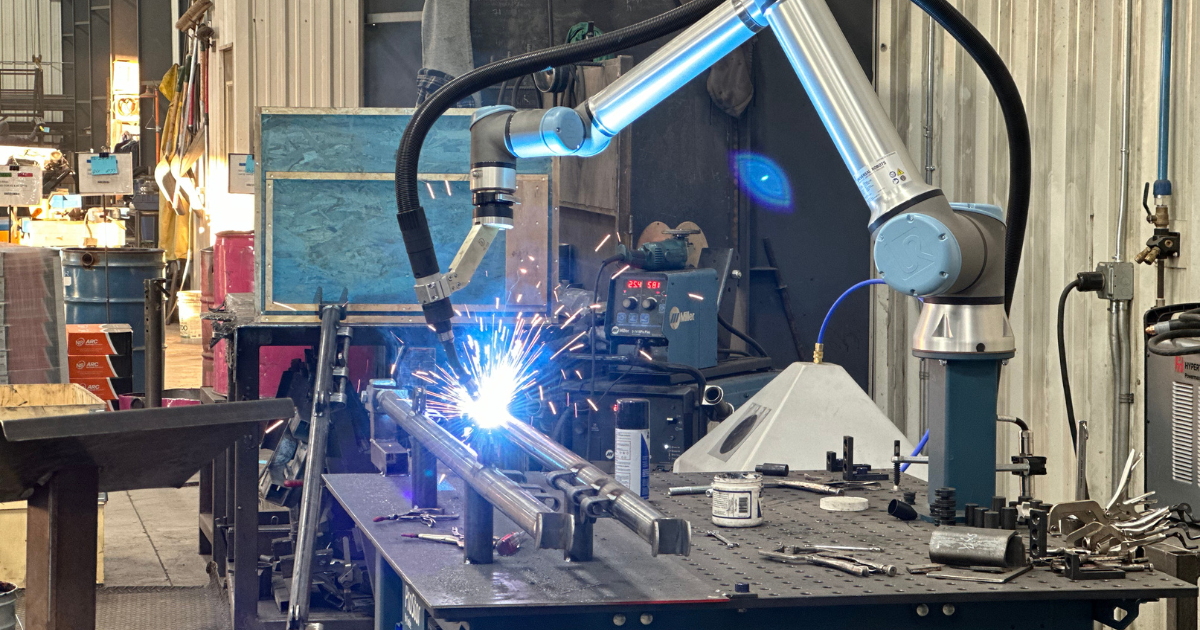

At MJE Livestock Equipment, we’re excited to announce the latest addition to our manufacturing toolkit: the state-of-the-art Lancer™ Collaborative Robot (COBOT) welding system. This advanced technology represents our commitment to staying at the forefront of the industry, combining cutting-edge manufacturing techniques with our steadfast dedication to quality and durability.

The Power of COBOT: Enhancing Efficiency and Precision

The COBOT welding system is a game-changer in metal fabrication, especially for companies like MJE that prioritize efficiency and product quality. With its collaborative design, COBOT works alongside our skilled welders, augmenting manual processes to improve throughput, enhance precision, and lower production costs.

American-Made Quality Meets Technological Advancement

As a proud producer of American-made cattle and livestock equipment, MJE LE’s investment in the COBOT welding system underscores our mission to offer only the best to our customers. This machinery aligns with our values of delivering durable, high-quality equipment crafted with meticulous attention to detail.

Training for Excellence: Our Welders Take the Lead

Our best welders have undergone extensive training to master the COBOT system. They’re ready to harness its capabilities to create more robust, reliable products.

“I think this is a really cool system. We spent some time training, and it’s going well so far. Setting it up takes a little work, but once it gets rolling, it just goes on its own. We can have someone nearby to monitor it, but that person can also be working on their own thing at the same time.” says welder “Red” Medford.

Collaborative Welding: A Step Into the Future

The COBOT system is designed for close collaboration with human operators, ensuring that our welders remain integral to the production process. This human-robot partnership enables us to maintain the handcrafted quality MJE is known for while embracing the benefits of automation.

“I think it’s going to be so good for us,” says Marco Gutierrez, lead welder. “It will make us much more efficient in the shop, and the welds are so good. We’re going to be able to work a lot faster in the shop.”

Customization at Its Finest: Adapting to Unique Fabrication Needs

One of the COBOT’s standout features is its flexibility. The system’s 5/8 inch peg hole compatibility and programmable nature mean we can quickly adapt to different project requirements, ensuring that each piece of equipment meets our stringent standards and our customers’ unique needs.

Environmental and Spatial Advantages: A Leaner Manufacturing Footprint

COBOT’s compact design and built-in water-cutting table contribute to a leaner manufacturing footprint. By optimizing space and reducing environmental impact, we’re improving our workflow and minimizing our ecological footprint—a win-win for MJE Livestock Equipment and the environment.

A Complete Metal Fabrication Platform: Adding Plasma Cutting Capabilities

With the ability to integrate a Hypertherm® Powermax® plasma cutting system, our COBOT isn’t just a welding solution—it’s a complete metal fabrication platform. This versatility allows us to perform high-quality cuts and welds with unprecedented precision.

MJE LE Is Geared for the Future

Adding the COBOT welding system to MJE Livestock Equipment’s manufacturing process is more than an upgrade—it’s a statement. It reflects our ethos of blending time-honored craftsmanship with modern innovation. We’re not just prepared for the future but actively shaping it, ensuring that our customers always receive equipment that embodies excellence.

Experience Innovation

Witness the difference that the COBOT welding system makes. Visit us at MJE Livestock Equipment to see how we’re using technology to enhance the durability and quality of our American-made livestock equipment.

MJE Livestock Equipment loves to offer tours of our facilities to students, dealer partners, and anyone interested in learning more about how MJE Livestock Equipment is made.

Please stop by our facilities at 800 W. Cortez St., Montezuma, KS 67867, to see it in action!